Electric cars: special training courses for practical use

SEHON is opening a new training center to impart expertise in the practical handling of electric vehicles such as BEVs, HEVs, PHEVs, FCEVs and the like, which can be used by companies, associations and anyone involved with electric cars for information, training and further education purposes. The technology company sees this as an important addition to the high-voltage training courses for workshops at levels S to 3S and for production, research and development at levels E to 3E.

According to Statista 2023, there are around 36,000 vehicle workshops in Germany, of which 14,000 are brand workshops and 22,000 are independent workshops. According to new studies, over 430,000 people work in the automotive industry. The handling and repair of electric vehicles – which place new safety requirements on businesses – creates new risks for operational, work and workplace safety. It is the responsibility of company owners, managing directors and department heads to ensure this safety in their own company.

“Accident and illness statistics alerted us years ago and prompted us to take action,” says Tiemo Sehon, “due to the strict safety regulations for multi-material mix bodies, we knew very early on what service companies and workshops were facing with electric vehicles. Today, as then, we know that companies are unfortunately often not sufficiently informed and equipped. That is why we have decided to help improve this situation with our new training center. Nobody wants companies, employees and the environment to be exposed to potential dangers from safety deficiencies without protection, especially not the company owners.”

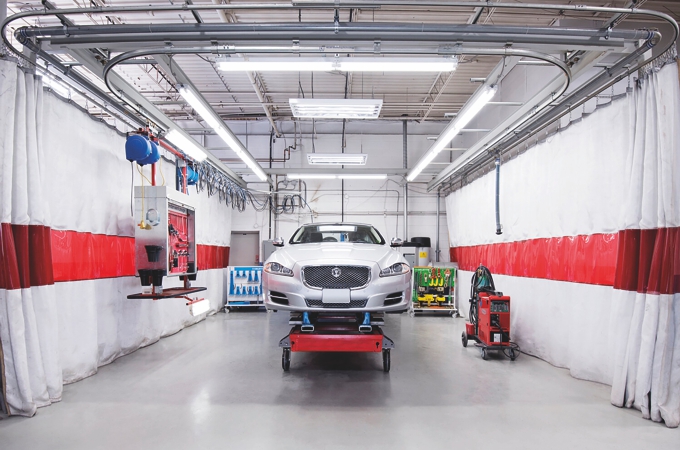

CAMELEON E-Station. Safe workplace for the repair of electric cars.

According to SEHON, CAMELEON, the first safe and professional car body workstation for processing car bodies made of different materials such as aluminum, carbon, steel and plastic (multi-material mix), was created in 2016. Knowledge about the safe handling of hazardous materials and material combinations, sparks, dust, substances and smoke has been continuously expanded and implemented in corresponding legally compliant products for electric vehicles.

Today, SEHON offers a wide range of professional workplace systems for the safe handling and processing of modern vehicle bodies. This primarily includes electric vehicles (BEV, HEV, PHEV and FCEV). The CAMELEON system from SEHON ensures safety in operation and at the workplace, including problem solving in the event of accidents, defects and the disposal of electric vehicle batteries. It not only complies with German and European standards, laws, norms and directives, but also the even stricter US standards and regulations.

With the high-voltage training courses in accordance with DUGV Information 209-093 for servicing electric vehicles (workshops) and for the development and production of electric vehicles (manufacturers), important steps have been taken for the handling of electric vehicles by employees. But what happens now in practice?

Tiemo Sehon: “Safe operations, safe workplaces, safe work processes and safety for nature and the environment must not be a coincidence and must not be underestimated by anyone. A single electric car can not only cause car freighters to burn down – as happened recently – but also entire companies. You can play down such accidents and turn a blind eye. But it is clear that the company owner is liable for all damage caused by safety deficiencies in the company.”

At the CAMELEON Training Center, companies and their employees receive valuable practical support. How should a safe workplace be equipped for electric vehicles and other new forms of drive? What data and information must be measured and documented? What protective measures need to be taken? What minimum equipment is required? What equipment and products are available on the market? How can you recognize reputable and safe products?

Other important training topics include the risk assessment of the company, ATEX / explosion protection and its safeguarding, building fire insurance, occupational health and safety and workplace safety, avoiding explosions and early detection of potential risks to life, building safety and the environment. And for those with a practical orientation, the CAMELEON Training Center will be open for live testing, trial and evaluation. Another item on the agenda is the qualified answering of practical questions from participants. A certificate of attendance is awarded at the end of the training course.

“In technical occupational safety,” says Tiemo Sehon, “70% of safety comes from knowledge, 30% from the right equipment. And that is exactly what we offer to everyone involved with electric vehicles. Knowledge transfer for operational practice. Interested companies and workshops are cordially invited to visit our new training center.”

Anyone interested in a practical training course can contact SEHON informally by e-mail. Due to the minimum number of participants of 10, it is also possible to plan the training with a friendly company and take part together.

Author: Michael Teschke

In the Training Center: CAMELEON Systems.

Safe repair of electric cars with a system.

A training room at the SEHON Training Center.